Damaged Truss Repairs Florida

At EMA Structural Forensic Engineers, our experienced structural engineers offer structural analysis and design of damaged wooden trusses. If you are looking for an alternative to utilizing a truss manufacturer, or you are needing a damaged truss repair system design that a truss manufacturer cannot design, we can help. Our experienced structural engineers can design lumber trusses of all types with efficiency and safety in mind.

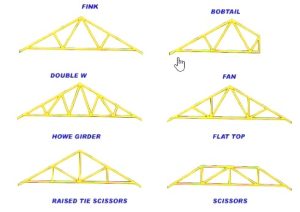

There are a variety of shapes, styles, and sizes of lumber trusses available. Each wooden damaged truss repair design is specific to the type of loading that it will encounter. Besides a regular-shaped wooden truss, some of the most popular truss styles include:

-

- Scissors Truss: Sloped bottom chord allows for more ceiling height on the floor below sometimes used for vaulted ceilings.

-

- Polynesian Truss: This dual-pitched roof truss usually has two significantly different roof pitches from heel to peak.

-

- Cathedral Truss: Mostly used to provide a partially vaulted ceiling.

-

- Gambrel Truss: Usually used when designing barns and other like structures. Sometimes used when building an attic space.

-

- Attic Truss: Used to provide storage space in the attic. The important defining feature of this truss is that it uses a larger/heavier timber bottom cord to carry the applied loading.

Damaged Trusses Repair Engineers Florida

Truss damage repairs are engineered components design and repair details prepared after a truss failure. When damaged or altered this can affect the structural integrity of the roof system. Localized structural damage to one or two trusses will typically not result in structural failure of the roof system but could cause the roof or ceiling to sag. In residential construction, this can also be a problem when selling a house because home inspectors often find damaged roof trusses which need to be fixed by truss damage repairs details.

Roof trusses are engineered components. When damaged or altered this can affect the structural integrity of the roof system. Localized damage to one or two trusses will typically not result in structural failure of the roof system but could cause the roof or ceiling to sag. In residential construction, this can also be a problem when selling a house because home inspectors often find damaged roof trusses. Because trusses are engineered components, typical building codes specify that repairs or alterations must be designed by a registered design professional. In most cases that would be a Licensed Professional Engineer with experience in designing repairs or alterations to trusses.

Typical wood roof trusses consist of members-called chords and webs, that are connected with metal plates. Relatively small metal teeth protrude from the plates and the plates are pressed into the wood members using thousands of pounds of force for each joint. It is tempting to look at these plates and assume that a few nails would do the same job, but that is not the case. It takes many nails to equal the capacity of a typical connector plate. When using nails to join truss members it is also necessary to use lumber, plywood, or Oriented Strand Board (OSB) to join the members. Sometimes structural screws are also used for truss repairs. For typical roof trusses used in light-frame construction, bolts are usually not used because of spacing requirements. Even when nails or structural screws are used spacing must be considered and the fasteners used at the repaired joint or member extend much further from the joint or crack than a metal connector plate.

We have designed repairs for many roof trusses. We also can perform truss repairs. Sometimes it is more cost-effective or expedient for BCI to design, perform, and certify the repairs instead of designing the repairs, producing the necessary documentation to provide to a contractor, and then inspecting the repairs. It is not uncommon for contractors to overlook requirements. It is also sometimes difficult to correct improperly performed repairs.

Wood Damaged Truss Repair Drawings

Typical truss repairs consist of several members called chords and webs that are connected with metal plates. Relatively small metal teeth protrude from the plates and the. plates are pressed into the wood members using thousands of pounds of force for each joint. It is tempting to look at these plates and assume that a few nails would do the same job, but that is not the case. It takes many nails to equal the capacity of a typical connector plate. When using nails to join truss members it is also necessary to use lumber, plywood, or Oriented Strand Board (OSB) to join the members. Sometimes structural screws are also used for truss repairs. For typical roof trusses used in light-frame construction bolts are usually not used because of spacing requirements. Even when nails or structural screws are used spacing must be considered and the fasteners used at the repaired joint or member extend much further from the joint or crack than a metal connector plate.

We have performed many roof truss damage repairs. We also can perform complete engineering details and drawings for roof truss damage repairs. Sometimes it is more cost-effective or expedient for BCI to design, perform, and certify the repairs instead of designing the repairs, producing the necessary documentation to provide to a contractor, and then inspecting the repairs. It is not uncommon for contractors to overlook requirements. It is also sometimes difficult to correct improperly performed repairs.